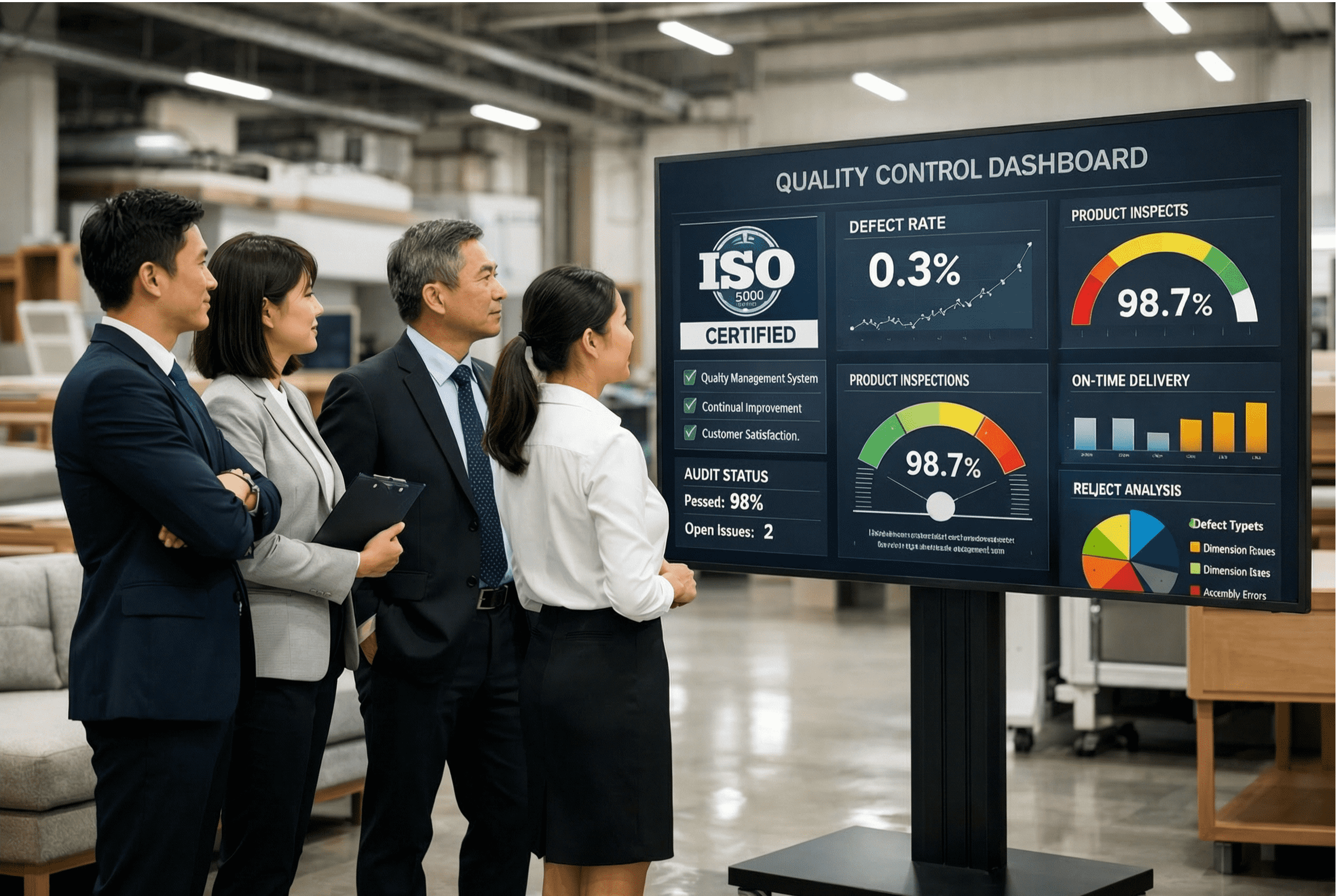

Zero-Compromise Quality at Every Checkpoint

Quality isn’t inspected in—it’s built in. ISO 9001-certified protocols protect your brand and minimize returns.

Surface & Finish Inspection

Showroom-perfect. No exceptions.

We Check:

• Zero scratches, dents, chips, or uneven coatings

• Spectrophotometer-verified color consistency

• Smooth, splinter-free edges with sealed veneers

• Precise wood grain, marble, and fabric pattern matching

• Taut upholstery with secure stitching

• Corrosion-free hardware with uniform plating

<0.5% reject rate

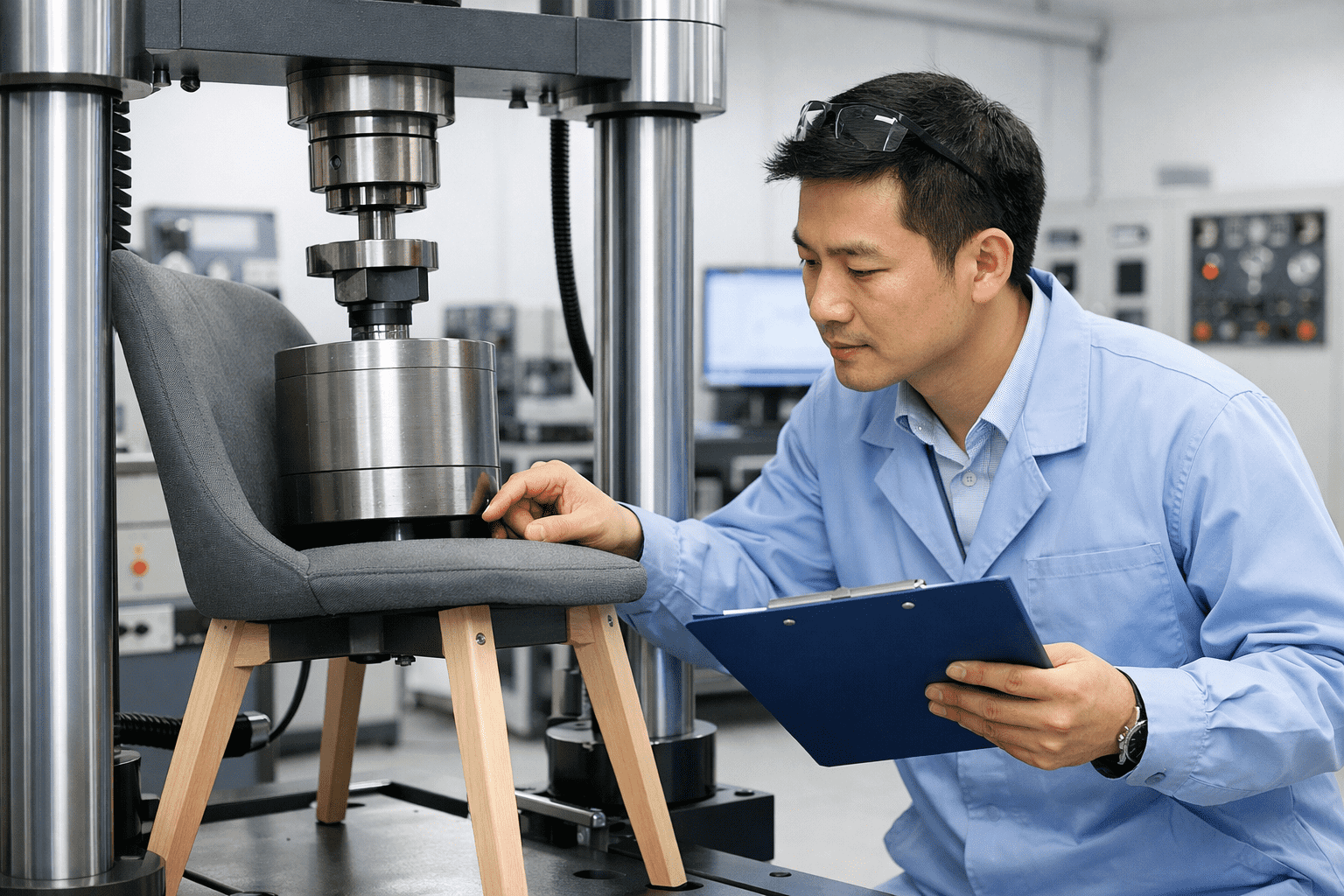

Structural & Assembly Integrity

Beauty without strength is meaningless.

Real-World Testing:

• Torque testing on all connections

• Load testing 30% beyond rated capacity

• Four-point stability verification

• 5,000+ cycle mechanism testing

• Compression and torsion on all frames

Standards: BIFMA, EN 12520, GB 28007

Packaging & Transit Protection

Arrives pristine. Guaranteed.

Protection:

• Multi-density foam on vulnerable areas

• Moisture-resistant cartons (200# strength, reinforced)

• Hardware separately bagged and labeled

• Complete documentation verified

• Correct SKU and handling labels

<0.3% transit damage

Drop Test & Shipping Simulation

ISTA-standard testing ensures zero transit failures.

Protocol:

• Multi-angle impact testing (ISTA 3A)

• 500kg stacking simulation for 72 hours

• Long-haul vibration simulation

• Temperature/humidity cycling

• Full photo documentation

Result: Proven shipping compliance. Fewer claims. Fewer returns.

Third-Party Verification Welcome

SGS, Bureau Veritas, or your QC inspectors. Full transparency.

Quality you trust. Consistency you count on.